With the support of Ford Australia, the hub offers equipment, programs and mentorship to help young Australians explore opportunities in ...

School's new STEAM hub excites students

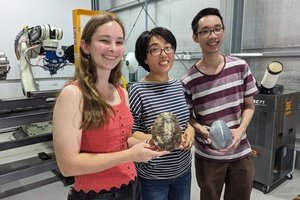

A new STEAM Hub at Victoria’s Northern Bay College (NBC) has really sparked the interest of students and staff alike.

This story appeared in the March 2018 edition of Australian Teacher Magazine.